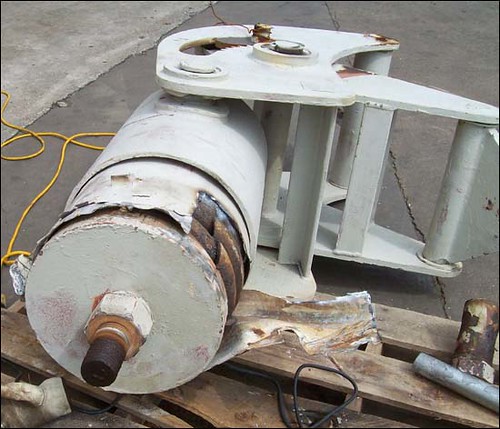

This initial order included PT&P’s field services division testing and recalibrating four constant spring supports not manufactured by PT&P. A preliminary inspection of the original constants revealed deformations in the spring coil housing. This is indicative of defective coils; therefore, before any load tests were conducted, inspection windows were cut into the spring coil cover to confirm the initial hypothesis (Figure 2). Inspection of the coils revealed complete deterioration with broken and missing sections of the spring. Subsequent inspections of the remaining three assemblies illustrated similar failures. The original constants were then disassembled (Figure 3) to determine the feasibility of replacing only the coils while utilizing the original frame/cam components.

The original spring coils were different in spring rate, length, and diameter than any standard PT&P coils; therefore, multiple coils were required to duplicate the overall function of the existing coils. Using multiple coils also required modifications to the existing frames. In an effort to expedite the overall delivery schedule, entirely new constant springs were manufactured in one week (Figure 1). The four new constants measure 53″ long, 13″ wide and 86″ tall. They have a 18-3/4″ diameter spring coil with a coil housing of 20-1/2″ diameter. The new constant assemblies are designed for an operating load of 13,332 lb., travel of 13″ upward and 2″ downward for a combined total travel of 15″. A load test throughout the total travel range was performed on each constant.

Want to learn more about constant springs? Watch a recording of a past constant webinar today!