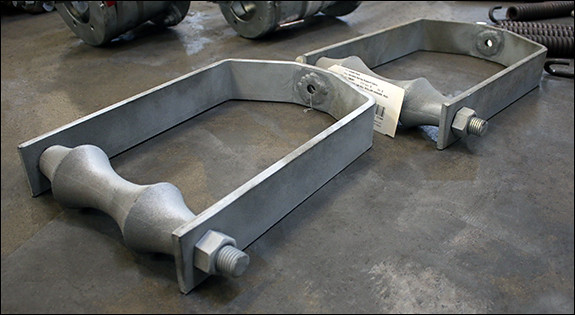

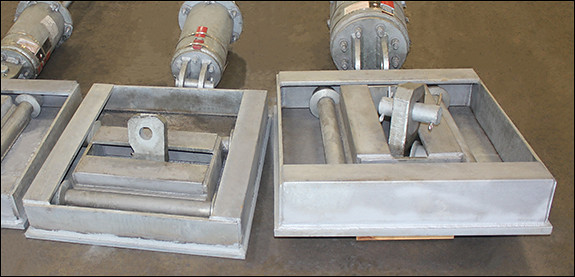

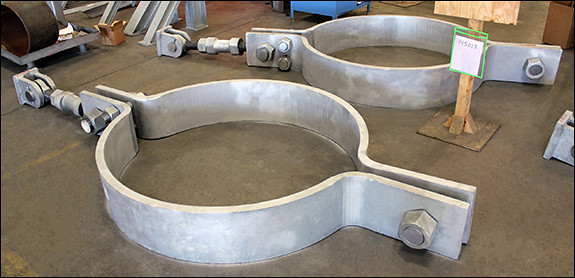

Piping Technologies & Products fabricated these special designed Split-T pipe shoes using a Figure 50 “two-bolt pipe clamp” with added gusset plates welded beneath the clamps for a refining project in Saudi Arabia. The gusset plates are added to increase the vertical load-carrying capacity. The pipe shoes are 4″ height x 15.5″ wide x 18″ long and were fabricated from A36 carbon steel with a hot-dipped galvanized finish. They are designed for a pipe size of 14″ with an operating temperature from -29°C to 316°C. The pipe shoes are capable of supporting an operating load of 34,000 lb.

We provide such products in a “clamp-on-shoe” configuration to meet the needs of client applications where welding the pipe shoe onto the process line is prohibited. Depending on the client’s specifications, we can design and manufacture these shoes without a finish (black) or various painted finishes in place of hot-dipped galvanizing to expedite the delivery of the order. We can manufacture these clamp-on-pipe shoes with different metallurgies, such as 304 or 316 stainless steel, to accommodate high temperatures or cryogenic applications depending on the project’s needs. This basic pipe support is used in industries ranging from automotive, petrochemical, LNG, and refining in almost every major processing unit to maintain pipe elevations and handle loads imposed by media movement.

PT&P REF. ORIGINAL POST 07112016

Read More