|

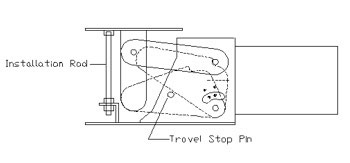

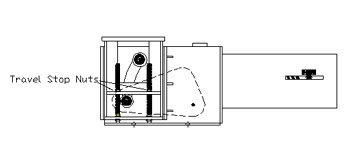

PT&P received an emergency phone call from a petrochemical plant in the Persian Gulf. There was a ½” gap between the load flange of the Constant Spring support and the Trunion of the process line while the plant was in operation (Fig 1). Our expert field engineer was immediately dispatched to the client site to investigate the issue. An inspection of the products in question revealed that the travel stop nuts were bolted down. This prevented the support table from moving and supporting the pipe (fig 2).

Figure 2 |

|

Travel Stop Removal is one of the most important tasks that must to be done when installing a spring support. Travel stops should be removed after Hydro testing when the pipeline is at the “Cold Load.” When the stops are left in place, “piping loads” are transferred to the piping system instead of being absorbed by the springs. Some of the results of this are: • Damage to pump equipment In 30 – 40% of the plants that PT&P visits for site inspection or hanger maintenance issues, there is at least one spring hanger with the stops in place. (Fig 3) The possible reasons for this are: • Improper Installation

The following procedures should be followed when installing spring cans. These can be used for either Variable Load supports or Constant Load Hangers which are supported from the top. Bottom supported constants are discussed below. 1. Attach upper attachment(s). For more detailed instructions please see our installation and maintenance guides: For F-type Constants (Fig 5.) 1. Secure base plate of the constant to the supporting structure.

For U type Constants (Fig 6.) 1. Attach base plate to supporting structure

It is also important not dispose of the travel stops once the springs are installed. They will be useful during scheduled maintenance. Anytime that you are going to open up a pipeline with springs on it, you should replace the travel stops. It We offer: • Site inspection – inspection of existing supports to determine their condition and recommend other changes. PT&P can and has worked in many places around the US and the World; we have over 30 years of experience in the pipe support industry. We are confident in our ability meet any challenge that comes our way. |