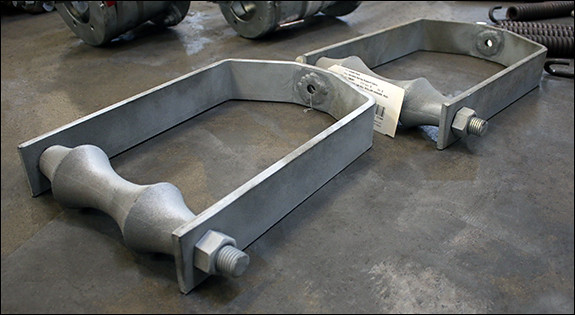

| Type: | Roller Hangers |

| Size: | 12″ Wide and 15″ Tall |

| Material: | Cast Iron & Carbon Steel |

| Design: | 965 lbs. Operating Load & 10″ Pipe Size |

| Testing: | Standard Quality Control |

These Fig. 195 roller hangers were designed by PT&P for an aviation facility in California. They measure 12″ in width and 15″ in height. The rollers are fabricated from cast iron, with the yoke, roll rod, and hex nuts from carbon steel. The units are designed for a pipe size of 10″ and an operating load of 965 lbs. Standard quality control tests were performed prior to shipment. Roller hangers are used for the suspension of pipe from a single rod where axial movement may occur because of expansion or contraction. These are often used on bridges where pipelines cross waterways such as rivers and bayous. If there is extensive traffic, they can be used in conjunction with variable springs to accommodate such factors as vibration, wind, and other external factors. This particular job is an excellent demonstration of our ability to support quick turn request to meet the needs of our clients as it was shipped before the contract date in less than a week’s time.

Our roots are deeply embedded in the petrochemical, power, energy, and refining sectors. We remain adaptable, constantly seeking opportunities to contribute to pivotal projects. Our recent diversification into various industry verticals encompasses participation in both private and public sector space exploration. Additionally, we play a pivotal role in the flourishing 11.2 billion-dollar data center industry, driven by advancements in AI and its widespread adoption.

Time-to-market is a paramount consideration for our projects. Leveraging our Houston-based manufacturing facility, we stand out as a market leader, possessing the capability to support large volumes within tight timeframes. This agility is particularly crucial for the time-sensitive nature of semiconductor, pharmaceutical, EV battery, and automotive production facilities.

PT&P REF. ORIGINAL POST 04022018

Read More