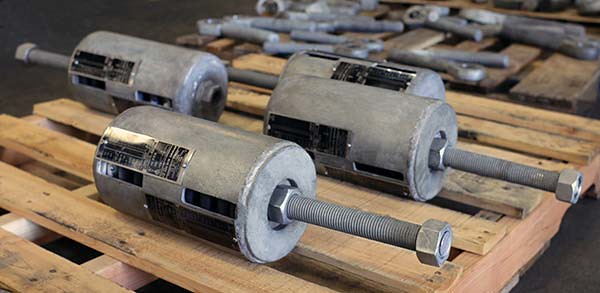

PT&P designed and manufactured these variable spring hanger assemblies for a Flue Gas Cooler and SCR system in Thailand. The SCR system utilizes urea to reduce NOx levels. These variable spring hanger assemblies incorporate the use of three-bolt pipe clamps (fitted with metric bolting for this overseas order) ranging in sizes from 6″ to 12″ diameter with elevation differences ranging from 68-½” to 138-1⁄2″ from the pipe rack structure steel member to the center of the pipe. The B-Type spring hanger assembly uses coil springs to support the load and allow for vertical movement. They are furnished with one lug welded to the top of the spring’s transition plate. The transition plate can be designed for different connection arrangements utilizing 2 lugs or a threaded connection. All forty-seven variable spring supports were quality-checked with a 100% spring coil deflection test utilizing a load cell to also set the assemblies at the prescribed installed load. These spring hanger assemblies were packaged for export shipment at our facility.

Variable supports are typically used for the following considerations in piping systems:

- Compensating for Thermal Expansion

- Maintaining Stress and Load

- Installation in Piping Systems

- Maintenance

- Supporting Heavy Loads

Variable spring cans play a crucial role in maintaining the integrity and stability of piping systems by compensating for thermal expansion or contraction, supporting heavy loads, and allowing for vertical movement. They are essential components in industries such as petrochemical, power generation, semiconductor, refining, paper and pulp processing, and other applications where large-scale piping systems are employed.

Variable spring cans come in a variety of designs and are constructed using different materials to suit specific applications and environmental conditions. Materials commonly used for variable spring cans include carbon steel, stainless steel, and special alloys. The selection of materials is crucial to ensure that the device can withstand the corrosive effects of certain fluids or harsh environmental conditions.

Variable spring supports, along with our array of engineered support solutions, stand as a fundamental pillar of our business. They enable us to actively collaborate with our clients, whether it involves the products we’ve manufactured, systems subjected to pipe stress and Finite Element Analysis (FEA), or items serviced through the expertise of our field service team.

PT&P REF. ORIGINAL POST 02232016

Read More