In many situations, fixed equipment must be able to move in axial and/or lateral directions.

Surfaces where controlled movement is desired are ideal for Piping Technology’s PTFE Slide Plates. Typically, you will find these slide plates underneath pressure vessels or other heavy equipment, such as pumps and compressors, that must be able to move freely along their support surfaces to prevent unplanned outages or operational downtime.

Without PTFE Slide plates, friction between metal components puts your equipment at risk of misalignment, ruptured lines, or anchor failures, which in turn shortens the lifespan of both piping and equipment.

PTFE (polytetrafluoroethylene) slide plates help prevent these issues by providing a low-friction interface, enabling smooth movement.

What’s at Stake in the Field

Whether it’s a pipe shoe sliding on a beam or a heavy vessel on embedded steel, surface friction can lock systems in place, causing stress and damage. Without the right slide interface, steel-on-steel friction causes wear, cracking, and eventually system failure.

PTFE slide plates resolve this issue by reducing friction and maintaining structural alignment, which is especially crucial during thermal cycling. As temperatures fluctuate, pipes expand and contract, and the slide plates allow for this pipe movement without stressing supports or causing misalignment.

How PTFE Slide Plates Work

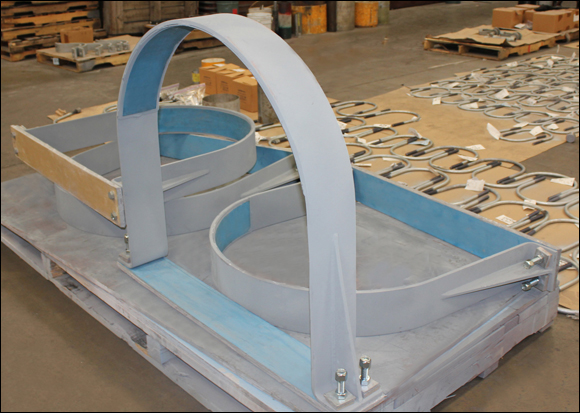

PTFE slide plates are two-part assemblies. PTFE is bonded to a carbon steel bottom plate and is also bonded to the top plate, which makes up the slide plate assembly. Once the bottom assembly is attached to the existing steel and the upper assembly is connected to the bottom of a pipe shoe or trunnion, a low-friction surface is created, allowing for both axial and lateral movement. The PTFE layers are mated from the upper and lower assemblies, allowing movement between the moving component and a fixed support beam or surface.

The result: Easy, controlled movement that reduces load transfer to anchors, minimizes friction, and extends equipment life.

Real-World Example: Natural Gas Pipeline Using PTFE Slide Plates

An international pipeline construction company partnered with us to supply PTFE slide plates for a major gas pipeline project in Africa.

The slide plate assemblies supported pipe shoes mounted on structural steel beams, accommodating both axial and lateral movement while maintaining structural stability..

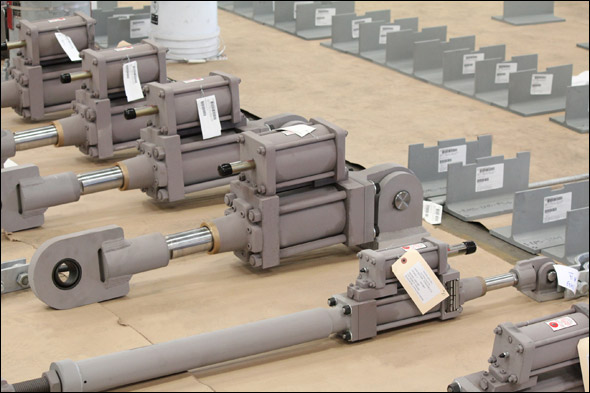

We engineered and delivered twenty guided cradle supports, ranging in size from 8″ to 30″. Each was fabricated from carbon steel and painted for corrosion resistance.

Thanks to our in-house inventory of PTFE, we accelerated production and avoided costly field delays, delivering exactly what the project needed, right on time.

Where PTFE Slide Plates Are Used

- LNG terminals

- Petrochemical plants

- Refineries

- Power plants

- Beneath equipment like pumps and compressors

- On spring supports

- Bridges: Highway bridges, overpasses, railroad bridges

- Cross-beam and girder slip joints

Key Benefits of PTFE Slide Plates in the Field

- Produces a low coefficient of friction between a stationary support element and the moving pipe support component

- Enables controlled pipe movement to prevent overstress during thermal expansion

- Ideal for low-heat and high-velocity conditions.

- Minimizes friction between steel components, reducing wear

- Pairs easily with other supports like pipe shoes and spring cans

- Operates effectively from –320°F to +500°F, maintaining its low-friction properties across this wide temperature range

Engineer’s Take: Why Choose Our PTFE Slide Plates

PTFE slide plates are a trusted choice for engineers thanks to their high load-handling capacity, consistent low-friction performance, and long-term durability.

We offer sizes ranging from 4″ x 4″ to 12″ x 12″ (and larger if needed), engineered to support both lateral and axial movement without compromising structural integrity.

Unlike most suppliers, we stock PTFE in-house, ensuring faster lead times and dependable availability. We can custom-manufacture slide plates to your exact specifications, including custom shapes, thicknesses, and bonding requirements.

PTFE is easy to install, requires no surface treatment or grouting, and performs reliably in all weather conditions, making it a smart, low-maintenance solution for demanding applications.

Project Manager’s Take

From the project manager’s perspective, these plates solve several key problems: they reduce rework caused by misaligned pipe shoes, eliminate costly delays waiting for movement-compatible supports, and help preserve the integrity of anchors and foundations. With our rapid turnaround and in-house inventory, you can keep the installation on track and avoid any extended wait time.

Products Often Paired with PTFE Slide Plates

PTFE slide plates are commonly ordered with:

- Pipe shoes

- Hold-down clamps

- Type F variable springs

- Big Tons

- Spectacle Blinds

- Embed Plates

- Pipe Saddles

Why Choose Piping Technology for Your Slide Plate Needs?

At Piping Technology, we stock over one million pounds of mixed inventory (including PTFE), enabling us to manufacture custom slide plates quickly and ship them fast.

Our slide plates are available in a range of materials, including PTFE, graphite, bronzphite, stainless steel, and more, to meet the unique demands of your project.

We specialize in engineering cost-effective, custom solutions for complex piping challenges. Consult with one of our engineers today to discuss sizing, compatibility, or application needs, or Request a Quote to get pricing and lead times for your next project.

Read More