When vertical piping in a high-pressure system starts to shift, everything downstream is at risk. Hanger misalignment, accessory failure, and field delays would be the least of your worries when vertical pipe systems experience axial displacement.

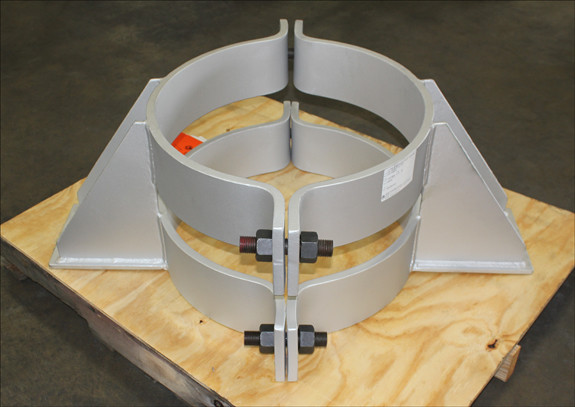

That’s where Piping Technology & Products’ custom riser clamp assemblies deliver assurance engineers can count on. With the proper design specifications, PTP can manufacture precision riser clamps that ensure secure and reliable product delivery.

Purpose-Built for Vertical Load Control

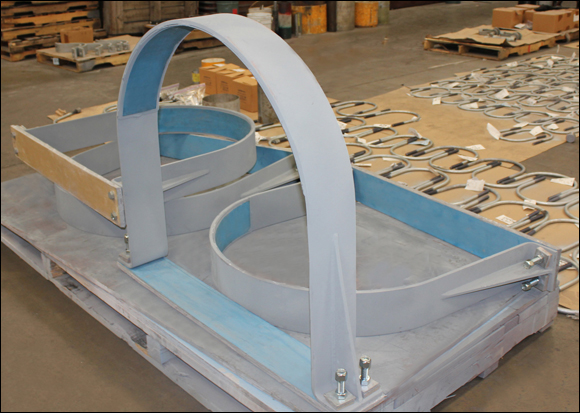

Riser clamp assemblies are specifically engineered for vertical pipe systems where axial movement must be restricted. It is not a one-size-fits-all product. Each assembly is fabricated to fit exact pipe diameter, temperature, and load specifications, most commonly for critical process lines in synthetic gas, petrochemical, or tall vertical rack applications.

At its core, the assembly relies on a heavy-duty steel clamp secured around the pipe, working in tandem with thrust plates to manage axial loads.

For high-heat applications, manufacturers utilize A387 alloy steel (rated for service temperatures of 750°F to 1,000°F) and a high-temperature coating that won’t degrade or flake under scorching conditions.

Once installed, the clamp limits movement in the downward direction, ensuring the pipe doesn’t slip under load or due to temperature expansion. Engineers often pair the clamp with spring hangers or sway struts for a complete load path solution.

Real-World Application: Synthetic Gas Plant Retrofit

At the request of a synthetic gas facility, PTP engineered a custom riser clamp assembly for their high-temperature vertical piping. We used Alloy A387, a heat-resistant steel specifically selected for service temperatures reaching up to 1,000°F, to fabricate this assembly.

To ensure performance under thermal cycling, we coated the clamp with a high-temperature industrial-grade coating designed to withstand prolonged exposure without degradation. By preventing vertical slippage during system startup, the clamp maintained alignment integrity and eliminated the risk of early rework or other types of damage to the pipeline.

Common Use Cases for Riser Clamp Assemblies

Riser pipe clamp assemblies serve a critical role in applications where vertical piping must be securely supported and restrained.

Engineers commonly use them on vertical risers in fired heater loops, where high temperatures and axial loads demand reliable restraint. They also support tall structural pipe racks in petrochemical plants, ensuring alignment across multi-level piping systems.

In high-rise and offshore environments, riser clamps provide secure anchoring for firewater systems subject to seismic or dynamic loading. Additionally, LNG facilities rely on them for vertical steam lines that require thermal movement control and long-term integrity.

Key Benefits for Field Execution

PT&P’s custom riser clamp assemblies provide clear advantages for vertical piping systems.

They prevent pipe slippage by firmly securing the line in place, ensuring axial stability under load.

Each assembly is custom-sized to match the exact pipe outer diameter, specified load, and temperature range, eliminating fit-up issues during installation.

PT&P designs these supports to handle pipe sizes up to 48 inches and fabricates them with high-temperature materials and coatings that perform reliably in scorching environments.

Engineers apply Finite Element Analysis (FEA) to optimize steel thickness, reduce excess material, and validate structural integrity.

By managing design, fabrication, and delivery in-house, PT&P minimizes handoffs and reduces the risk of delays or errors throughout the supply chain.

Why Engineers Choose Riser Clamp Assemblies

Engineers value this clamp for its precision and structural integrity. Load ratings are validated through FEA, ensuring that the clamp can stand against almost any surprise event. For jobs with elevated temperatures or non-standard loads, our custom approach removes guesswork from spec compliance.

Why Project Managers Chose Riser Clamp Assemblies

What sets these clamps apart is how they minimize scope creep.

When clamp assemblies are properly designed from the start, there’s no field modification, no install surprises, and fewer RFIs. The result: less rework, better schedule control, and a clear value add during procurement planning.

Other Items Often Purchased with Riser Pipe Clamp Assemblies

- Variable and constant spring hangers

- Pipe shoes and saddles

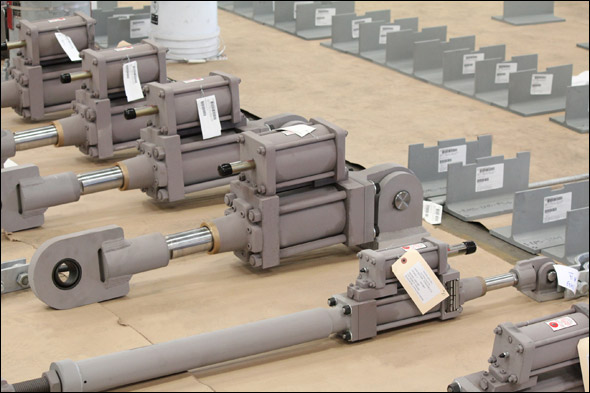

- Sway struts and sway braces

- Hydraulic and mechanical snubbers

Talk to an Engineer

Need a riser clamp that fits your piping system? Our team is ready to review your load, pipe size, and environment to build the right assembly fast.

Request a Quote or Talk to an Engineer today.

Read More