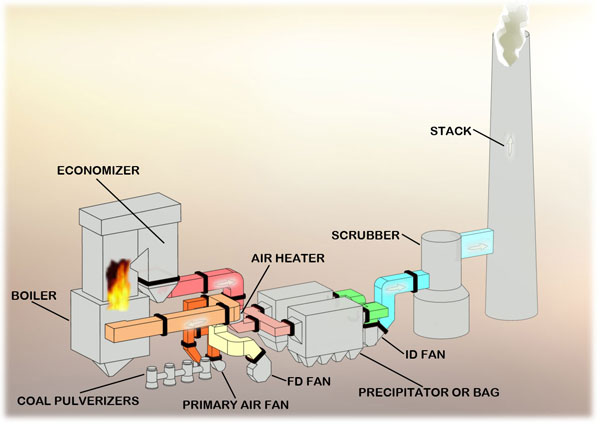

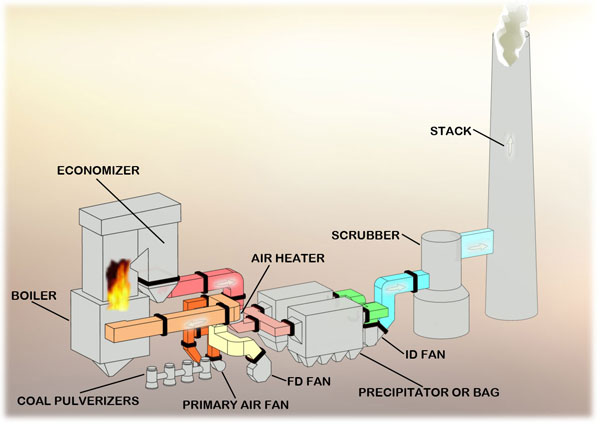

An industrial furnace, also known as a direct heater or a direct-fired heater, is a device used to provide heat for an industrial process. Furnace designs vary as to their function, heating duty, type of fuel, and method of introducing combustion air. Heat is generated by an industrial furnace by mixing fuel with air or oxygen, or from electrical energy. The residual heat will exit the furnace as flue gas. Types of industrial furnaces include batch ovens, vacuum furnaces, and solar furnaces. Industrial furnaces are used in applications such as chemical reactions, cremation, oil refining, glasswork, metallurgy, mechanical engineering, chemicals, ceramic, and building materials. Industrial furnaces using fossil fuels are characterized by heat losses from flue gases with a temperature of 500°C and above.

PT&P supplies many products that are well-suited for furnace applications. The first category we’ll take a look at is Engineered Spring Supports. We size furnace springs the same way as we would for a conventional variable or constant spring support. Construction may include a welded design instead of bolted and custom nameplates with the test data and ID tag. Most furnace spring supports are coated with red oxide primer to avoid potential hazards when exposed to high temperatures.

PT&P specially designed and fabricated hundreds of altered Type A Variable Spring Hangers in order to accommodate the special travel and spring rate needed to support the furnace tubes of a hydrogen reformer in Venezuela. In order to accommodate customer-specified travel and spring rate, modified spring coils were required. With a travel of 8-7/8″, the variable spring hanger casing lengths were increased from the standard size of 32″ to over 6′ long. The calculated spring rate is 79 lb/sq in for an operating load of 2,804 lb. and an installed load of 3,505 lb. The housings are coated with heat-resistant paint, which protects the spring coils from corrosion and high temperatures in the furnace area.

Expansion Joints are not installed inside furnaces due to the extremely high temperatures of the environment and the piping system. Expansion joints will typically be found on the duct work and in the piping coming in and out of the furnace. In the last six months, we have shipped over 40% of our expansion joint jobs in less than 2 weeks to meet customer project deliverables.

Fabric Expansion Joints that are in-service near furnaces, typically include a 3-layer belt consisting of Silicone, Fiberglass, PTFE, and Mineral Wool Insulation. The configurations are either round, rectangular or square as seen in the examples below.

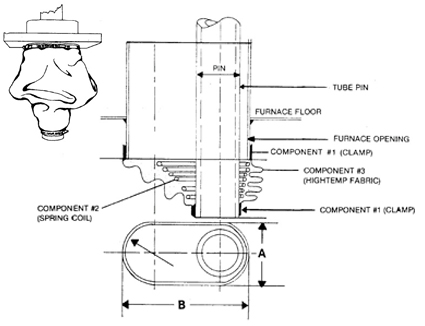

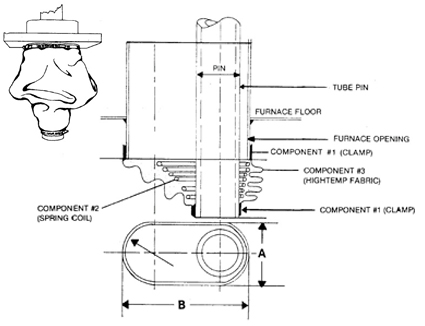

Furnace Bags are used to seal high-temperature tubes that penetrate the furnace floor. The furnace bag consists of multiple layers of flexible, flame and heat resistant, impervious fabric designed to operate from start-up to high-temperature design conditions. The bag will expand and contract with the varying furnace temperatures.

Stainless steel clamps or band straps connect one end of the pipe that goes through the penetration opening and the other to another sleeve in the furnace floor. A tapered steel coil is installed around the conduit inside the bag to prevent the fabric from collapsing inward during vacuum conditions. PT&P’s standard furnace seal bag is nickel reinforced, with a special coating that reduces airborne fibers and increases tensile strength.

PT&P REF. ORIGINAL POST 11092021

Read More