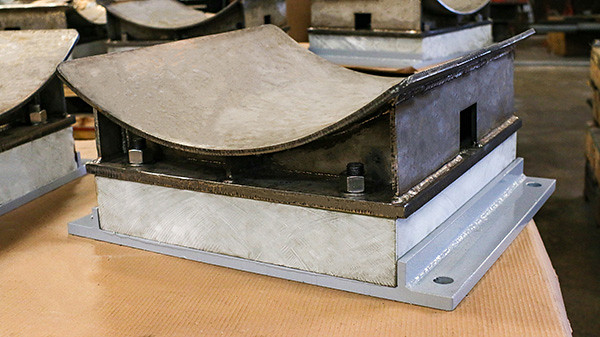

| Type: | Variable Spring Supports |

| Size: | Rod Diameter 2” / Casing 8′ long & 3 1/8” Diameter |

| Material: | Carbon Steel |

| Design: | Operating Load 31,563 lbs., Installed Load 29,000 lbs., 0.82″ Downward Movement |

| Testing: | Standard Load & Travel Tests |

PT&P designed two standard PTP-4 size 210 A-type variable spring supports for a process power plant in Oklahoma. The springs are fabricated from A36 carbon steel with a hot-dipped galvanized finish. The springs are designed to accommodate a hydro test load of 34,000 lbs. with an operating load of 31,563 lbs. and an installed load of 29,000 lbs., with the movement of 0.82″ downward. Standard load and travel tests were conducted on the variables before shipment. The specially designed springs utilize a rod diameter of 2″ and the spring casing 8′ long and 3 1/8″ in diameter.

In addition to the products we offer, we also have an experienced field service team. Over 80% of the field service we do is for engineered supports, including constant and spring supports. Inspecting pipe supports in high-energy piping systems such as refineries, chemical plants, and power plants is critical for ensuring safety and reliability. Neglecting these inspections can lead to major consequences detailed below:

- Structural Failures: Over time, pipe supports can weaken due to corrosion, vibration, or other factors. Without inspection, undetected defects can result in the failure of these supports, causing pipes to sag, bend, or even rupture. This can lead to catastrophic accidents and expensive repairs.

- Leakage: When pipe supports degrade, they may cause pipes to shift or disconnect, leading to leaks at flange connections and other types of connections in high-pressure systems caused by pipe strain. These leaks can release hazardous substances, causing environmental damage, health risks, and operational disruptions.

- Reduced System Efficiency: Improperly supported pipes can experience increased friction, causing higher energy consumption to maintain the desired flow rates. This inefficiency can result in increased operational costs and decreased overall system performance.

- Loss of Containment: In high-energy piping systems, failure to inspect supports can compromise containment integrity. A pipe rupture or leak called a “failure in the pressure-containing boundary,” can release hazardous materials, posing serious risks to personnel, nearby communities, and the environment.

- Regulatory Non-Compliance: Many industries are subject to regulations and standards governing the inspection and maintenance of high-energy piping systems, including ASME B31.1 and 31.3 and API570. The implications of non-compliance can result in legal consequences and fines.

- Increased Maintenance Costs:With regular inspections, minor issues can be managed so they do not escalate into costly and timely major problems such as extensive repairs or complete system replacement.

- Loss of Productivity:Unexpected failures and repairs can disrupt production schedules and lead to unplanned downtime, causing financial losses and impacting the company’s reputation.

Correct installation and regular inspections are essential to mitigate risks and ensure industrial facilities’ safe and efficient operation. We have a team of engineers and technicians who are qualified to inspect pipe supports and expansion joints and can assist with diagnosing problems, replacement, and identifying models, types, and sizes. We provide field service to our clients for all product categories we manufacture, even if we are not the OEM because serving our clients is our first priority.

PT&P REF. ORIGINAL POST 11272017

Read More