Project-Driven Pipe Clamp Fabrication Delivered in 8 Weeks

A construction firm set out to build a 256-mile natural gas pipeline across Ohio to meet the growing energy needs of the Midwest. A few challenges: ensuring that support components for the 42-inch diameter line could meet technical requirements and scheduling demands with no room for error.

To ensure the safe and long-term operation of its piping systems, the project team turned to Piping Technology & Products (PT&P) to design and deliver more than 100 custom-fabricated pipe clamps

Project Requirements and Pipe Clamp Design Specifications

The project managers could not afford delays, rework, or compliance issues from unsuitable pipe clamps that did not adhere to engineered specifications.

What the project demanded:

- Custom-manufactured clamps for 42-inch OD pipe

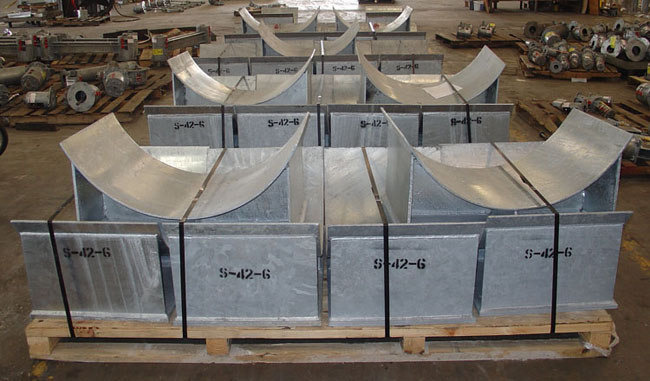

- Hot dip galvanized for outdoor exposure, which would minimize future maintenance needs

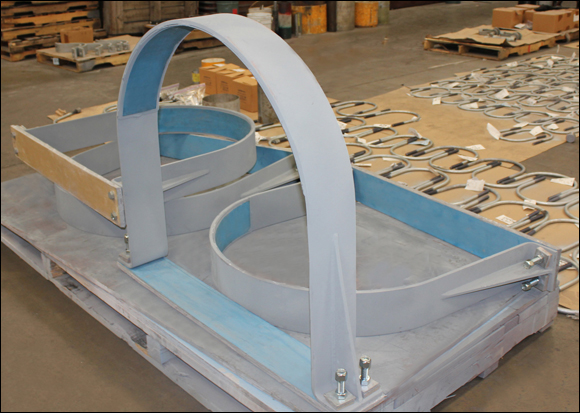

PT&P engineered and manufactured 110 heavy-duty pipe clamps tailored to this job’s exact needs from our Houston facility.

Technical Highlights: How the Pipe Clamps were Built

- Pipe Diameter: 42 inches

- Clamp Width: 12 inches

- Material: A36 carbon steel body with bonded vibration control materials (Other options: Neoprene, PTFE, isolation pads, Fabreeka®, and more)

- Fabrication: In-house manufacturing

- Quality Control: Visual examination and fit-up verification for pipe OD were conducted before shipment to meet industry-standard inspections

- Delivery: 8 weeks, end-to-end

Engineer’s Take: Structurally Sound and Specification-Driven

Engineers on this project required proof that their supports would withstand the field conditions. Our clamp design included bonded wear pads to protect the pipe from damage and corrosion. All materials were verified to meet MSS SP-58 guidelines, ensuring long-term performance with no compromise on safety.

Project Manager’s Take: Zero Rework, On-Time Delivery

Avoiding schedule slippage was critical. By validating technical requirements at each stage, we avoided rework, reduced delays, and delivered with confidence. Our 8-week turnaround and proactive communication, which included scope reviews, design approvals, milestone check-ins, and regular updates, eliminated guesswork. Every clamp arrived jobsite-ready, clearly labeled, spec-compliant, and fit to install with no field adjustments.

Why Project Managers Choose PT&P Pipe Clamps

- Short Lead Times: Most of our products have an 8-week turnaround time, even on complex builds

- Built to Spec: Made to your specs, no compromise on fit or load (standard products are also available)

- Made in the USA: Full fabrication and QC from our Houston facility

- Production Scalability: Capable of supporting both small-volume and high-volume orders

Clamp Configurations We Offer

We manufacture a wide range of pipe clamps, including:

- Standard pipe clamps

- Adjustable clamps

- Riser clamps

- U-bolts

- Fully custom configurations and options on materials and coatings

Most complex builds are fabricated to order at our Houston facility to meet exact project needs, whether that’s load rating, environmental resistance, or non-standard diameters.

By delivering precisely engineered, high-quality clamps, PT&P supported the safe and efficient development of this state-wide pipeline project. We are proud to support cleaner energy transitions by enabling fuel switching from coal to gas and allowing access to lower-cost shale gas reserves.

Most large-scale projects require tailored designs like this one. That is why, with recent investments in our manufacturing operations, we are uniquely positioned as the only manufacturer to provide high-quality, custom-made solutions for your piping systems to our clients faster and on a larger scale than ever.

Need Project-Specific Pipe Clamps?

Our ability to design and manufacture sets us apart, providing confidence and assurance to our clients and their customers that we will strictly adhere to their specifications and job site requirements.

We’re one of the few U.S. manufacturers with in-house engineering, custom fabrication, and full quality control (QC) capabilities for high-specification pipe clamps.

Talk to an Engineer about your next project or Request a Quote today.

Read More