Maintain Production Flow, Prevent Downtime, and Protect Pipeline Integrity

As debris builds up inside long pipelines, it becomes increasingly difficult for the media to flow. If left unchecked, this buildup can compromise safety and trigger costly maintenance shutdowns.

Pig launchers provide a proven reliable, inline solution. Allowing for the insertion of pipeline inspection gauges, custom pig launchers are engineered for cleaning, separation, and inspection, letting you maintain pipeline performance without depressurization, keeping operations online and flow rates steady.

How a Pig Launcher Works

A pig launcher is a pressure-rated chamber that introduces a pipeline inspection device or “pig” into a piping system. A pig launcher is a pressure-rated vessel that safely introduces a pipeline inspection tool, commonly referred to as a “pig,” into a live system. Once loaded, sealed, and pressurized, the pig is pushed through the line by the flow of media or compressed gas. The pig removes debris, separates media, and/or inspects for defects along the way.

Each pig launcher unit includes:

- Major barrel for pig loading

- Minor barrel that ties into the mainline

- Quick-opening closure for safe, repeatable access

- Valves and flanges designed to meet your pressure, temperature, and media specs

CAN WE USE OUR PRODUCT SKETCH HERE FROM THE WEBSITE?

When paired with a receiver, it forms a complete pigging system, ideal for routine maintenance, pipeline integrity checks, or product batching without interruption to operations.

Case Study Example: High-Pressure Pigging System Built to Spec

A petrochemical plant needed a pig launcher and receiver package for two separate high-pressure lines. The design required tight alignment with operating conditions and quick field readiness.

Specs Delivered:

- System pressure: 740 PSIG

- Operating temperature: 170°F

- Barrel sizes:

- Set 1: 24″ minor × 30″ major × 138″ long

- Set 2: 10″ minor × 14″ major × 132″ long

- Material: API 5L X52 carbon steel

- Application: High-pressure process lines requiring regular pigging

- Design Code: ASME Section VIII, Div. 1

Each launcher was hydrotested by our in-house quality teams to the clients requirements, sandblasted, and externally coated for corrosion resistance. Units were fabricated to match line specs, fully documented, and shipped ready for installation.

Application Uses for Pig Launchers in the Field

Our pig launchers are routinely used in:

- Crude oil pipelines

- Natural gas transmission lines

- Petrochemical and chemical process systems

- Refined product transportation, LNG terminals and compressor stations

Where flow assurance and cleanliness matter, pigging systems are standard practice.

Key Benefits of Pigging Systems for Your Project

- Inline maintenance keeps the product moving without system shutdowns

- Custom-built to match pipe diameter, pig dimensions, and service pressure

- ASME U-stamped with complete test documentation and hydrotesting

- Quick-opening closures reduce labor time and improve safety

- Corrosion-resistant finishes extend product life in demanding environments

- Full traceability and QA/QC documentation delivered with each order

- Short lead times and responsive project coordination

Engineer’s Take: Designed for Field Integrity

Engineers specify our pig launchers because they’re engineered for real-world performance:

- Sized for your pig and pressure class

- Built from API-grade steel for mechanical strength

- Precise CAD modeling is available for integration and layout planning

- Instrumentation ports available for pressure monitoring or automation

- Documentation packages include MTRs, weld maps, and hydrotest records

No guesswork. Every unit arrives with data that validates the design.

Project Manager’s View: Predictable, Field-Ready, and On Schedule

From planning through installation, our systems help you keep projects on track:

- Pre-engineered fit means fewer RFIs and no retrofit risk

- Responsive engineering support keeps timelines moving

- Safe closures and access simplify routine maintenance

- On-time delivery prevents scheduling bottlenecks

- Clear documentation reduces approval cycles and install confusion

You’re not just buying a launcher—you’re gaining a partner who understands the cost of delay.

Related Products to Support Your Pigging System

Pair with these components to stabilize and protect your pipeline:

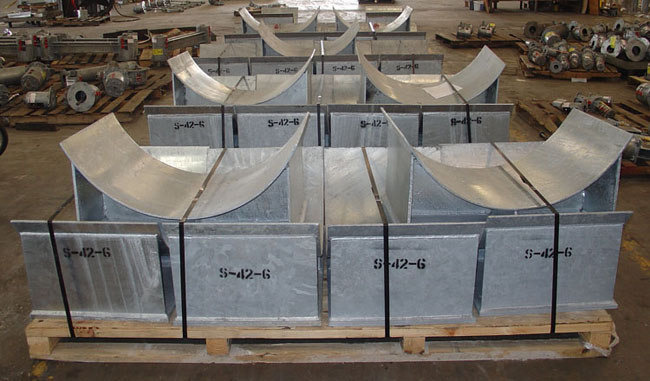

- Pipe saddles for large-diameter line support

- Spring hangers to accommodate thermal expansion near tie-ins

- Pipe anchors and guides for directional control during pigging

- Hydraulic snubbers to absorb transient forces and prevent joint damage

Each of these components is built to match your pigging layout and system dynamics.

Let’s Build Your Pig Launcher to Spec

Need a pig launcher that meets your pressure class, fits your system, and delivers on schedule? We’re ready.