Designed to prevent deformation and reduce stress at key support points, adjustable pipe saddles deliver fixed, stable support where movement is not an option.

Chosen When Precision Elevation and Structural Rigidity Are Non-Negotiable

Heavy piping systems under load can shift, sag, or deform, especially when unsupported over distance or exposed to vibration, thermal change, or movement, putting your process-critical fixed equipment at risk . Adjustable pipe saddles are engineered to eliminate those risks.

By locking the pipe into a fixed elevation and anchoring directly into structural steel or concrete, these supports maintain piping system alignment reduce localized stress prevent any long-term deformation in critical systems.

Why Engineers Choose Adjustable Pipe Saddles Over Adjustable Pipe Stands

Engineers will usually specify adjustable pipe saddles when systems require exact pipe elevation, concentrated load handling, and rigid structural anchoring that won’t shift under pressure. For projects where pipe supports must prevent movement entirely, rather than allow for it, saddles are the reliable, constructability built solution.

Adjustable Pipe Saddles vs. Fixed Pipe Saddles: What’s the Difference?

Adjustable Pipe Saddles

Adjustable pipe saddles feature a fixed-height saddle (the curved cradle that supports the pipe), but are mounted on adjustable vertical supports or stanchions. This allows the elevation to be fine-tuned during installation to match field conditions, which is ideal when construction tolerances, structural discrepancies, or elevation mismatches are likely.

How It Works:

- A seamless center pipe section can be rotated to raise or lower the saddle height.

- Pre-drilled base plates make anchor bolt installation fast and consistent.

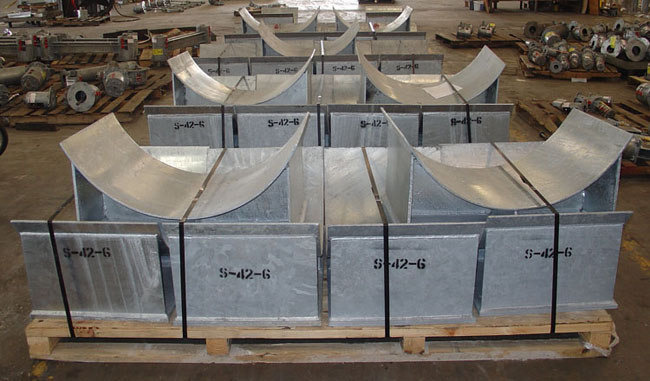

Carbon steel construction with red oxide primer or hot dipped galvanized coating ensures corrosion resistance in harsh environments.

Fixed Pipe Saddles

Fixed pipe saddles are completely static supports. Both the saddle and its structural stanchion are built to a specified height, with no option field adjustability. They’re designed when exact elevations are known in the piping system, to achieve maximum stability and zero movement under load.

Case Study: Adjustable Pipe Saddles for an Oil Refinery Retrofit in Michigan

When an EPC firm was retrofitting sections of a Midwestern oil refinery, they needed the infrastructure to support large process lines with varying elevations across aging foundations. We were able to design and manufacture custom adjustable pipe saddles for 24″ and 30″ diameter piping, fabricated from carbon steel and coated with red oxide to withstand Michigan’s seasonal shifts.

Adjustable Pipe Saddle Product Specs:

- Pipe Sizes: 24″ and 30″ OD

- Support Height: Adjustable from 40″ to 42″

- Material: Carbon steel, red oxide finish

- Adjustment Mechanism: Rotatable center pipe

- Delivery: Shipped within two weeks

The EPC team completed the install without site rework, saving time and ensuring alignment across uneven foundation grades.

Ideal Applications for Adjustable Pipe Saddles

Adjustable saddle supports are frequently used in:

- Oil and gas refineries

- LNG terminals and gas processing plants

- Petrochemical and chemical plants

- Power generation and utility facilities

- Pipe rack and sleeper systems in retrofit projects

Any application requiring elevation flexibility or working around existing steel is a strong fit.

Why Engineers Choose Adjustable Pipe Saddles

- Height adjustability eliminates field rework

- Faster installation that requires no welding or on-site modifications

- Pre-drilled base plates ensure bolt-down accuracy.

- Code compliant that meets ASME B31.3 and MSS-SP (Manufacturers Standardization Society Standard Practices) standards.

- Corrosion-resistant with protective coatings

- Available fast and quick turnaround to meet schedule demands

Why Engineers Choose Piping Technology & Products

Engineers trust us to supply them with adjustable pipe saddle that are:

- Load-tested and fabricated to custom project specs

- Adjustable within tight tolerances

- Available with full CAD support, drawings, and stamped calculations

- Built to meet ASME, ASTM (American Society for Testing and Materials), and NACE (National Association of Corrosion Engineers) standards.

The rotatable center section allows for precise elevation control, enabling engineers to dial in exact support heights without adding field modifications or compromising load-bearing integrity.

Why Project Manager’s Choose Piping Technology & Products

Project Manager’s value adjustable pipe saddles because they:

- Avoid schedule slip from misaligned piping or uneven foundations

- Reduce field RFIs and last-minute design changes

- Minimize costly rework and field welding.

- Fit into value-engineered packages that reduce labor and install time.

Adjustable pipe saddles make a project manager’s job easier, are built for changing field conditions, and are backed by a team that picks up the phone when it counts, 24/7. Our responsive engineering and quick-ship capabilities support fast-paced schedules, and our ability to align with field constructability needs—including work package-based production for module or scope schedules—helps keep projects on track from procurement to commissioning.

Adjustable Pipe Saddles are Usually Paired With:

- Pipe Shoes: for insulation or wear protection

- Variable Spring Hangers: for dynamic load balancing

- Anchor Clamps: for fixed points and thrust loads

- Embed Plates: for secure base installation in concrete

We are the only manufacturing company that engineers, fabricates, and ships all your pipe support needs from our manufacturing facility in Houston, Texas.

Talk to an Engineer

Are adjustable pipe saddles right for your next project? Talk with our engineering team about sizing, specs, and turnaround times.

Request a Quote

PT&P REF. ORIGINAL POST 03102013