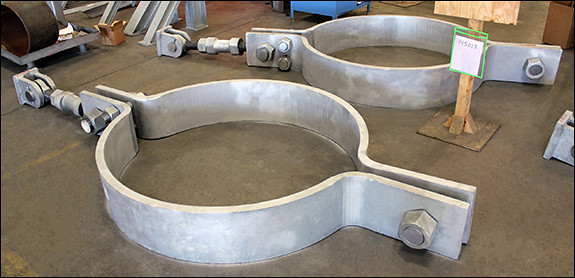

| Type: | Pipe Clamp and Sway Strut Assemblies |

| Design: | Operating load: 99,650 lb. | Temperature: 550°F |

| Material: | A36 Carbon Steel |

| Size: | Clamps: 149″ L x 14″ W x 2″ T | Load Bolt: 4-1/2″ | 68″ Dia. Pipe |

Piping Technology & Products custom designed pipe clamp and sway strut assemblies assemblies for an ethane cracker facility in Texas. The clamps are designed for a 68″ diameter pipe using a bar size of 149″ long x 14″ wide x 2″ tall. The load bolt size is 4-1/2″ and the inside bolts, rods, nuts, and turnbuckle are 4″ diameter. The assemblies are completely fabricated from A36 carbon steel, and designed for an operating temperature of 550°F with a load capacity up to 99,650 lb. A visual inspection test with sample pipe and dimensional check were conducted prior to shipment.