Introduction: Why this simple concept is a career game-changer

All industries combined spend literally billions of dollars per year in engineering and construction with one focus, the protection of the public through pipeline pressure boundary integrity assurance. Key to this goal is ASME B31.3. However, ASME B31.3 can be complex and ever-changing. Further, this piping code often references other complex ASME codes for further information and technical guidance.

If you’re looking to take your career to the next level, our ASME B31.3 Emerging Subject Matter Expert online course offers a deep dive into the practical and theoretical knowledge you need. With more than 10 hours of ASME-accredited content, it’s designed for our future ASME Subject Matter Expert engineers like you — ready to specialize, prepared to lead. Once you pass the final exam at the end of the full course, you will receive an ASME certificate of completion with 15-PE/PDH credits.

Demystifying Perceived Conflicts and Omissions in ASME B31.3

Industries go to great lengths in engineering analyses, construction/welding procedures and commissioning to assure public safety with high integrity final pressure boundary assurance of piping while paying only cursory attention in the codes to flange design and deployment. Flanges are a break in the pressure boundary and thus, should receive constant focus in the codes. Today’s high temperature flanges are virtually free of focus and remain a constant cause of process fires and hazardous leakage.

Additionally, constant threats to today’s elevated temperature ASME B31.3 piping pressure boundary integrity are

- Design Pressure and Temperature definition,

- Advanced pipe wall thickness calculations for high temperature, cyclic service

- Vibration,

- Expansion Joint design and troubleshooting,

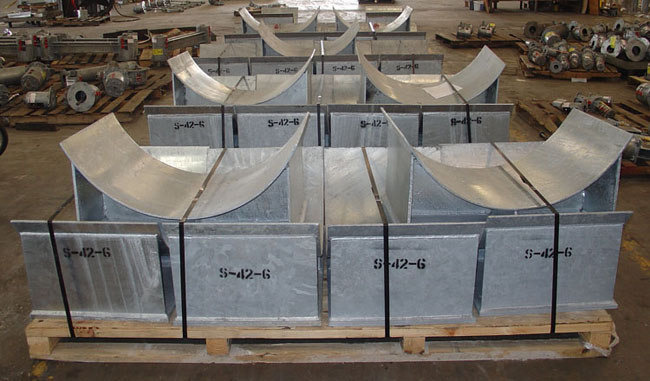

- Mitered bend design,

- Branch area replacement,

- Hydrogen service,

- Low temperature brittle fracture.

Industries that rely on ASME B31.3

ASME B31.3 applies to a range of sectors where process piping plays a central role. Here are a few:

- Oil and gas

- Chemical and petrochemical plants

- Pharmaceutical manufacturing

- Food and beverage processing

- Power generation

- Semiconductor fabrication

In these fields, learning ASME B31.3 online gives engineers the flexibility to study while working, helping them stay competitive and meet ever-evolving regulatory demands.

Why compliance with ASME B31.3 matters

Noncompliance isn’t just a paperwork issue — it’s a risk factor. Following process piping standards reduces the likelihood of leaks, failures, explosions, or costly shutdowns. It is required by liability insurance. It also ensures:

- Worker safety: Preventing injuries and fatalities.

- System reliability: Minimizing repairs and unexpected downtime.

- Regulatory approval: Meeting local and international codes for construction and operation.

Compliance signals competence. For engineers, it can mean the difference between stagnation and upward mobility.

Who should learn Seek an ASME B31.3 Subject Matter Expert Level?

While plant managers, quality assurance personnel, and project engineers all benefit from knowledge of B31.3, this course is especially critical for:

- Mechanical engineers moving into responsible piping engineering positions or construction roles.

- Project engineers supporting complex and critical piping design and construction projects.

- Inspectors and QA/QC specialists seeking to qualify for ASME B31.3 projects.

- Emerging engineers on the path to becoming SMEs looking for promotions or leadership designations.

Investing in an accredited online ASME piping course shows initiative and positions you as a valuable team member ready to take on more responsibility.

Learn from the best: Enroll in our Future Subject Matter Expert ASME B31.3 online certification course

At Piping Technology & Products, we’ve partnered with Michael Shelton, a Subject Matter Expert, for over fifty (50) years of hands-on ASME Piping and Pressure Vessel codes in numerous fields. Michael has been an a university adjunct graduate professor and taught industrial ASME courses for over twenty (20) years and is one of only three ASME B31.3-certified teachers.

Together, we have developed a high-impact ASME B31.3 Future Subject Matter Expert online program tailored to real-world applications. This piping design course for mechanical engineers offers:

- More than 10 hours of comprehensive video lessons

- Self-paced learning for working professionals

- In-depth coverage of real-world applicable case studies of the ASME B31.3 code

- 15 PE/PDH credits upon completion, with an ASME-certified certificate

- Immediate access to start learning right away

Whether diving into complex calculations or wanting to gain essential expertise in hydrogen piping design, this course equips you with the tools to master the code and stand out among your peers.

Or learn more on our online courses hub.

Final thoughts: Become the go-to expert in your company

ASME B31.3 isn’t just another code — it’s a blueprint for career advancement. As companies prioritize code compliance, risk mitigation, and technical expertise, engineers who’ve taken the initiative to get certified become indispensable. This isn’t just about knowledge; it’s about leadership.

Whether you want to enhance your credibility, lead projects, or prepare for promotion, the path starts with the right education. Continue on to your next title of Subject matter expert.

Start today — earn your credentials and elevate your career.

Read More